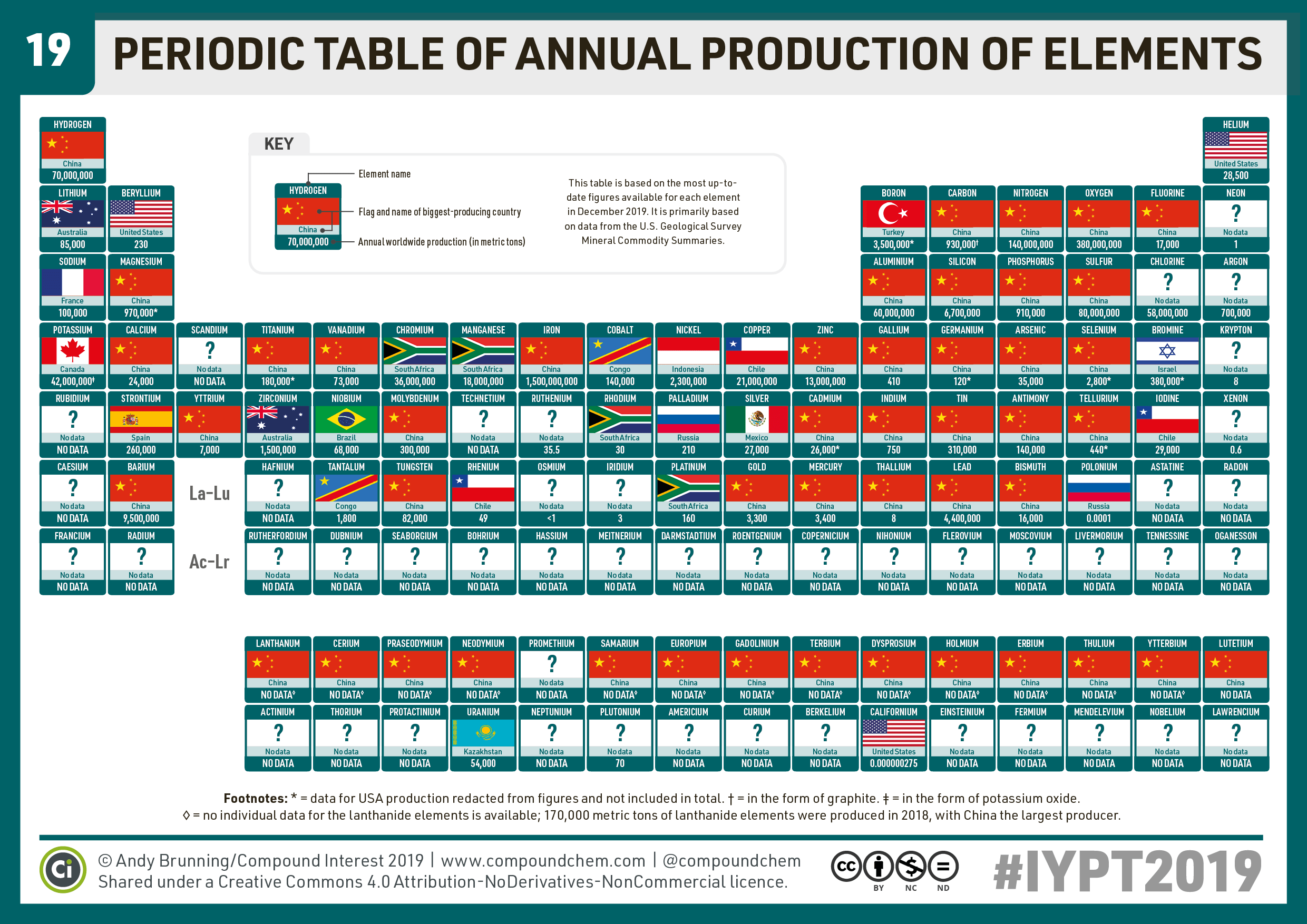

Ever wonder who's hoarding all the elements? Turns out China is basically the Walter White of the periodic table, dominating production of everything from aluminum to zinc. Meanwhile, the US is over here clinging to helium like it's the last Netflix password that works. The real kicker? Some elements have "NO DATA" because either nobody's making them or someone's being suspiciously quiet about their element stash. And Kazakhstan is just sitting there with their 54,000 tons of uranium, trying to look casual. This chart is basically geopolitics explained through chemistry. Next time someone asks why international relations are complicated, just point to this elemental turf war!

Academia

Academia

Ai

Ai

Astronomy

Astronomy

Biology

Biology

Chemistry

Chemistry

Climate

Climate

Conspiracy

Conspiracy

Earth-science

Earth-science

Engineering

Engineering

Evolution

Evolution

Geology

Geology